Complete Repair and Maintenance Services to Maintain Your Equipment Running Efficiently

Complete Repair and Maintenance Services to Maintain Your Equipment Running Efficiently

Blog Article

Experienced Lift Designer Providing Precision Repair Service Techniques for Lifts in Industrial Facilities

Lift Repair Service Competence

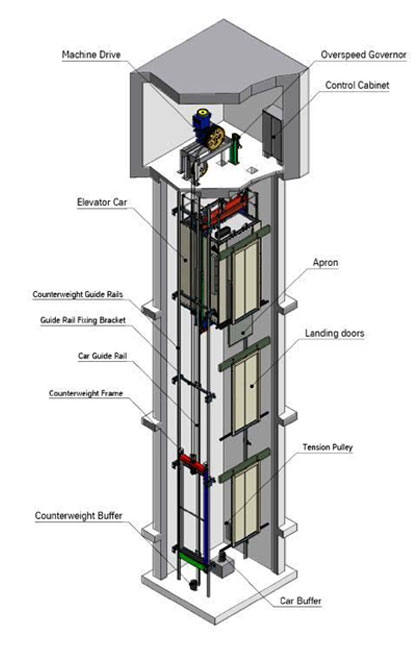

In the world of lift repair work competence, an extensive understanding of mechanical systems and electrical parts is paramount for efficient troubleshooting and upkeep. Lift repair work professionals have to have a deep expertise of just how these detailed systems work with each other to make sure the risk-free and trustworthy operation of elevators in industrial centers.

In addition, lift repair work experts need to be proficient at detecting concerns immediately and precisely to minimize downtime and stop prospective security dangers. They must have the abilities to analyze technical schematics, make use of diagnostic devices efficiently, and carry out proper repair work strategies. By staying abreast of sector developments and sticking to safety and security guidelines, elevator repair service technicians can provide trusted and effective repair service services that support the operational excellence of commercial elevators.

Accuracy Strategies for Maintenance

Making use of their competence in mechanical systems and electrical components, lift repair service technicians implement precision strategies for upkeep to make certain the continued secure and reliable procedure of industrial lifts. These knowledgeable professionals count on a methodical method that includes regular examinations, lubrication of relocating parts, modification of stress in cables, and replacement of damaged parts. By adhering to supplier guidelines and sector standards, lift technicians can detect potential problems at an early stage and protect against pricey malfunctions.

One important accuracy upkeep technique is the use of resonance analysis tools to monitor the problem of lift electric motors and bearings. By evaluating vibration patterns, technicians can identify abnormalities that might suggest impending failure, allowing them to take positive steps prior to a break down happens. Furthermore, precision placement of elevator shafts and pulleys is important to minimize deterioration on components and ensure smooth procedure.

Incorporating these accuracy upkeep strategies into a normal elevator maintenance routine helps extend the life-span of commercial lifts, minimize downtime, and enhance overall safety in industrial centers. - repair and maintenance services

Industrial Center Solutions

Utilizing ingenious technologies and strategic methodologies, commercial center services use extensive techniques for enhancing operational performance and optimizing productivity. Industrial facilities require tailored services to attend to the one-of-a-kind obstacles they deal with, such as complicated machinery, hefty tools, and rigorous security policies. These remedies encompass an array of services consisting of center layout style, tools upkeep programs, power efficiency improvements, and workflow optimization.

One secret element of commercial center options is anticipating maintenance, which makes use of information analytics and sensing units to keep track of tools performance in real-time. By identifying possible problems prior to they intensify, downtime is lessened, and functional interruptions are decreased. In addition, carrying out lean production concepts can enhance manufacturing processes, get rid of waste, and boost total efficiency.

Furthermore, industrial facility options usually entail the assimilation of automation systems to improve efficiency and make sure consistent result high quality. Automated procedures can take care of repetitive jobs with precision and rate, enabling workers to focus on more complicated procedures. Generally, these solutions are important for modern-day industrial facilities aiming to remain affordable in a vibrant market setting.

Troubleshooting and Development

Industrial center remedies lead the way for lift repair companies addressing functional challenges efficiently, with troubleshooting and innovation playing a vital duty in boosting upkeep methods and technical improvements within industrial settings. The ability to repair concerns quickly and effectively is paramount to make sure marginal downtime and optimum performance when it comes to elevators in commercial centers. Skilled lift designers are geared up with the experience to determine problems without delay, utilizing cutting-edge strategies to fix problems with precision.

Innovation in lift fixing within commercial centers includes the combination of innovative modern technologies such as IoT sensing units for anticipating maintenance, remote tracking systems, and information analytics for performance optimization. By leveraging these innovative remedies, lift engineers can proactively find possible concerns before they intensify, leading to expense financial savings and increased functional lift maintenance contractors performance.

Furthermore, fixing techniques include a systematic technique to identifying elevator breakdowns, including evaluating error codes, checking mechanical parts, and performing efficiency tests. By incorporating fixing methods with ingenious repair techniques, lift designers can provide high-quality upkeep solutions that make sure the smooth operation of lifts in industrial centers.

Smooth Lift Procedures

Effective lift procedures are important for making sure continuous and smooth operations within industrial centers. Elevator specialists play a crucial role in ensuring that elevators are operating efficiently at all times. By focusing on seamless lift operations, commercial facilities can improve safety, maximize logistics, and develop a conducive atmosphere for staff members to bring out their tasks successfully.

Conclusion

In verdict, the skilled lift engineer uses accuracy repair service strategies for lifts in commercial centers, ensuring smooth procedures and efficient maintenance. Their competence in troubleshooting and cutting-edge remedies add to the smooth functioning of elevators in these setups. With an emphasis on accuracy strategies, the engineer provides beneficial services to commercial facilities, permitting for secure and reliable lift procedures.

Elevator repair service technicians must possess a deep knowledge of just how these complex systems work together to make sure the trustworthy and risk-free procedure of elevators in commercial centers. By remaining abreast of market developments and sticking to safety and lift maintenance contractors security laws, lift repair service technicians can provide reliable and reputable repair service services that promote the operational excellence of commercial elevators.

Attracting on their know-how in mechanical systems and electric elements, elevator repair service service technicians execute accuracy strategies for maintenance to make sure the ongoing safe and trusted operation of industrial lifts. Lift professionals play an important role in guaranteeing that elevators are operating ideally at all times.In final thought, the skilled lift designer supplies accuracy repair strategies for elevators in industrial centers, ensuring smooth operations and efficient upkeep.

Report this page